Making A Prototype

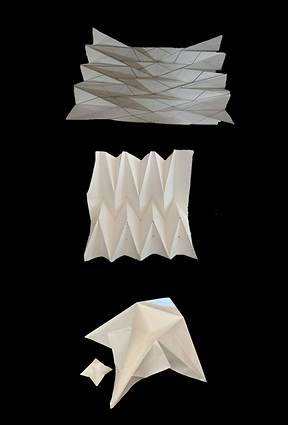

We initially focused on executing folds to develop steady forms on paper using simple geometries. Further, we developed these forms with materials like Aluminum wire mesh, Felt Paper, Clear OHP Sheet, Fiber Glass. Eventually concluding it with fiber glass, random mesh and resin.

We started with techniques of origami folds to create various stable forms on paper.

To create forms with OHP sheet, we used the method of half-cuts at the edges to create folds.

Felt paper when folded regained its original form due to its materiality, so a large amount of resin was required to obtain the desired form.

Aluminum mesh folded to achieve a stable form. The mesh is flexible and folds but the surfaces slightly bulge.

We proceeded with making a 1:1 scale object using fiber glass, fiber mesh and resin.

Object 1 - Bench

First we drew a grid on a sheet of fiber glass measuring 200 cm x 90 cm. The grid lines were covered with tape, so that the resin does not deposit at the folds. A mixture of 100 grams resin, 2 grams cobalt and 5 grams hardening agent is applied over the fiber glass in two layers. The object did not achieve a stable form due to less use of the hardening agent.

Object 2 - Side Table

The grid of the desired form was drawn on the fiber glass sheet of 200 cm x 80 cm and then covered with tape. Initially it was applied with a layer of mixture of 600 grams of resin, 15 grams cobalt and 18 grams hardening agent and to make the surfaces more strong and rigid, another layer of mixture of 100 grams of resin, 5 grams cobalt and 9 grams hardener was applied after folding, securing it with clips. When it had dried and became strong, it was covered with a wooden disc to form the table top. Unlike the bench, the table could take weight of objects placed at the top (about 8 kg).